KPI Services

Casing | Drill Pipe – BHA | Tubing | Roustabout | Trucking | Rental

Quality and Service

Kelly’s Pipe Inspection has the best equipment and people in the industry. We are driven by an unequalled dedication to our clients. A select list of Kelly’s Pipe Inspection clients is available through our account managers.

All Inspections Include:

- KPI Excellence

- Our Trusted Team of Experts

- Quality Over Site

- Customer Satisfaction

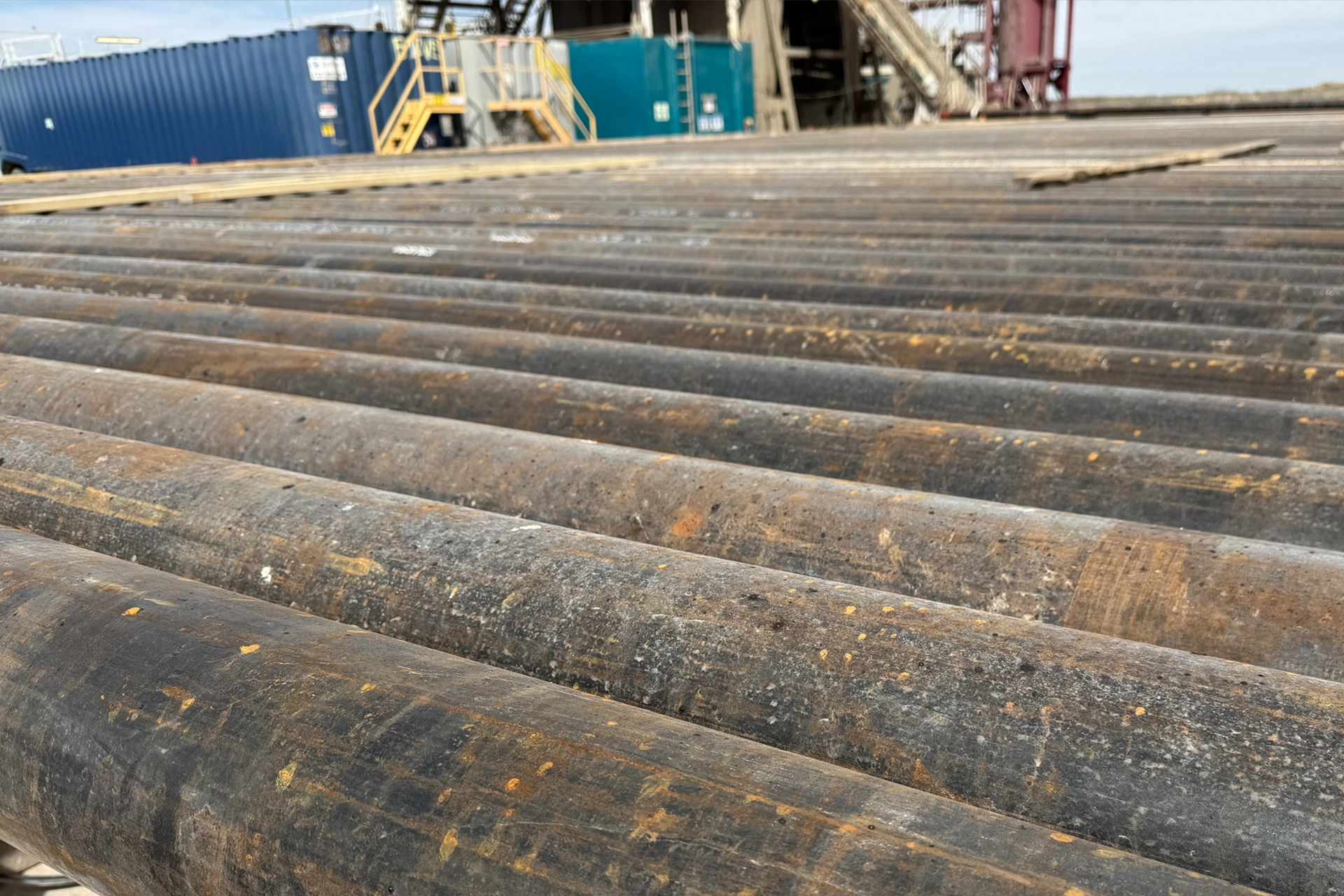

Casing

Body Inspection

We perform a thorough visual inspection of casing for obvious external damages such as corroded, dented, or bent tubes. Most damages arise from handling of the tubulars in transport.

Visual Thread Inspection (VTI)

We thoroughly clean, visually inspect, and evaluate both pin and box end connections for any damages. Damages include pitted, cut, mashed or galled threads. Any defects noted will be clearly marked on the joint of the pipe and identified on the inspection report.

API Drifting (Full-length)

An API drift cut to strict API specifications, is passed through the full-length bore of each length of pipe in order to check for mashed or dented areas along the pipe. If an area has been located, the defect will be noted on the inspection report.

Tally Services

A manual tape is utilized for this service. The data is entered into a proprietary program that outputs a report in excel. The tally can then be emailed to the customer.

UT Spot Check Inspection

In ultrasonic testing (UT), very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz are launched into materials to detect the thickness of your tubular materials.

Ring and Plug Gauge

The basic concept of a thread gauge is to provide a quick inspection to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly.

Thread Profile Gauge

Meticulous examination of thread profiles to ensure precision, adherence to specifications, and consistent product quality.

Drill Pipe – BHA

Drill pipe is subjected to stresses in tension, compression, torsion, and bending, so its inspection is essential to detect defects related to manufacturing, handling, and drilling. Our DP inspection services ensure DP is fit-for-service and extends your DP life cycle. Our comprehensive DP inspection program assists in maximizing your drill string performance and ensures your DP is fit-for-service before it is put in the hole. With a simple clean and visual inspection of 5% of any string that is new to location we can ensure you are receiving DP that has been properly inspected.

On the next full inspection, we not only identify damages but provide recommendations to reduce damages if they are not part of normal wear. For example, stabbing damage, over-torque, potential lack of thread compound and defective machining. Our goal is to prevent down hole drilling problems, ensure that you are paying for your damages not the previous user of DP, and guide your team in the proper handling and maintenance of DP.

Ultrasonic (UT), electromagnetic inspection (EMI), magnetic particle (MPI), and multiple dimensional checks are used to detect defects that are crucial to preventing downhole failures, saving you potential downtime and reducing costs.

Our inspections are performed in-plant or in the field. All tool joint and tubular inspection services are carried out in accordance with API or DS-1 standards.

Popular Services

Tubing

We are a full service tubing inspection house. We can inspect, repair or source any type of tubing required for the Job.

Roustabout

Our team of experienced roustabouts is dedicated to providing top-notch support for your rig activities. From equipment maintenance and repair to general labor tasks.

Rental

Rent tools and equipment for construction, industrial, and commercial projects.

Our Equipment & Services are Designed for Satisfaction

“Good people and a great Culture from the top down.”

“Great people and the best rig cookouts a man could ever ask for. I will never use another inspection company”